Pharmaceutical manufacturing is a complex and highly regulated industry that requires strict adherence to quality standards and regulations. One of the key challenges faced by pharmaceutical manufacturers is the need to maximize efficiency while ensuring product quality and safety. In recent years, consulting services have emerged as a valuable resource for pharmaceutical companies looking to improve their manufacturing processes and optimize their operations.

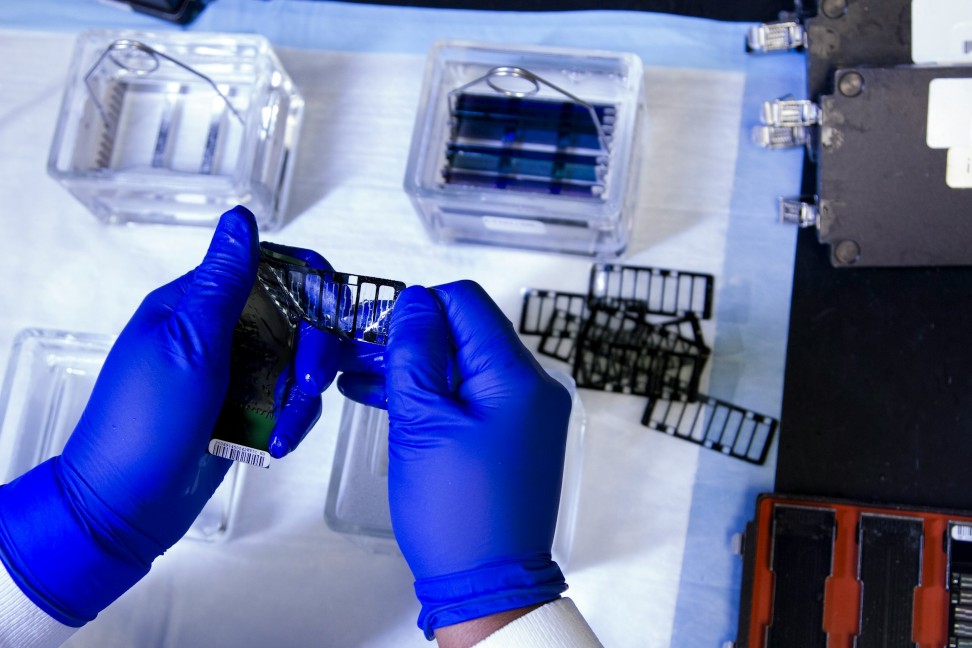

One area where consulting services can play a crucial role is in microbial contamination control. Microbial contamination poses a significant risk to pharmaceutical manufacturing processes, as it can lead to product spoilage, reduced shelf life, and even pose a threat to patient safety. Controlling microbial contamination requires a comprehensive approach that includes proper sanitation practices, environmental monitoring, and the implementation of robust quality control measures.

Consulting services specializing in microbial contamination control can help pharmaceutical manufacturers identify potential sources of contamination, develop effective control strategies, and implement best practices to prevent microbial growth in their manufacturing facilities. By working with experienced consultants, pharmaceutical companies can improve their manufacturing processes, reduce the risk of contamination-related issues, and ensure the quality and safety of their products.

One of the key benefits of working with consulting services is the access to specialized expertise and resources that can help pharmaceutical manufacturers address complex challenges related to microbial contamination control. Consultants with experience in this area can provide valuable insights and recommendations based on industry best practices and regulatory requirements. They can also help companies develop customized solutions that are tailored to their specific needs and requirements.

In addition to providing expert guidance, consulting services can also help pharmaceutical manufacturers streamline their operations and improve overall efficiency. By optimizing manufacturing processes, implementing automation technologies, and leveraging data analytics, consulting services can help companies reduce costs, increase productivity, and enhance the quality of their products.

Overall, maximizing efficiency in pharmaceutical manufacturing with consulting services can have a significant impact on a company’s bottom line and competitive advantage. By focusing on key areas such as microbial contamination control, pharmaceutical manufacturers can improve their operational performance, ensure product quality and safety, and maintain compliance with regulatory requirements.

In conclusion, consulting services play a vital role in helping pharmaceutical manufacturers maximize efficiency and achieve their business goals. By partnering with experienced consultants specializing in microbial contamination control, companies can enhance their manufacturing processes, reduce the risk of contamination-related issues, and ultimately improve the quality and safety of their products. By investing in consulting services, pharmaceutical companies can stay ahead of the competition and drive long-term success in the industry.

——————-

Visit us for more details:

Pharmalliance Consulting Ltd

https://www.pharmalliance.ie/

+353 (0)1 969 2000

Glasshouses GH2, 92 Lower Georges Street, Dun Laoghaire

Pharmalliance Consulting Ltd. offers practical expert advice to regulated Lifescience companies to increase FDA / EU cGMP compliance. We specialize in contamination control and can support you no matter your stage of development.

Pharmalliance offers specialist support to pharmaceutical companies to maintain and increase quality compliance levels.

We specialize in Contamination Control and have a suite of services to help you stay compliant no matter what your stage of development.